Granito tiles technical sheet

Composition of Granito tiles: Granito is a mineral material made of white Portland cement, marble powder, pigments for cement, and decorative aggregates of marble or coloured glass. These components are mixed with water and then moulded. Drying and hardening takes a minimum of 4 weeks. Then the Granito surface is polished - eliminating a layer of 1 to 2 mm - to unveil the beauty of the mix of coloured cement and marble or glass chips.

Applicable standards: There are no norms or regulations that are applicable to Granito products. The tests described below were carried out, at the request of our factory, following the norm UNE_EN 13748-1 for Terrazzo for indoor use. The UPEC classification does not cover this type of tiling, nor any of our other cement-based tiling.

Tests carried out in January 2016 by the Getinsa-Payma laboratory (Barcelona) on plain and patternes Granito tiles of size 20x20 cm and thickness 18 mm.

Flexural strength: 8,7 MPa

Standard : >= 4 MPa

Abrasion resistance: 14,0 mm

Standard : <= 25 mm

Surface water absorption: 0,17 gr / cm2

Standard : <= 0,4 gr / cm2

Slip resistance: USRV 46 value

Class 3 >URSV 45

- Interior surfaces with slope greater than 6º

- Wet interior surfaces or industrial surfaces

- Outdoor areas, swimming pools

IFA Laboratory, Germany, 2020

Result: total mean of inclination angle: 6,9º, Classification R9

The values of the Slip Resistance refers to the tile tested as delivered from the factory.

Notes regarding slip rates:

The more polished and shiny a surface is, the more slippery it becomes. Conversely, a matt surface polished with 60 grit will not be very slippery. The maintenance and application of wax, wether anti-slip or not, are not essentially affecting the slip rate.

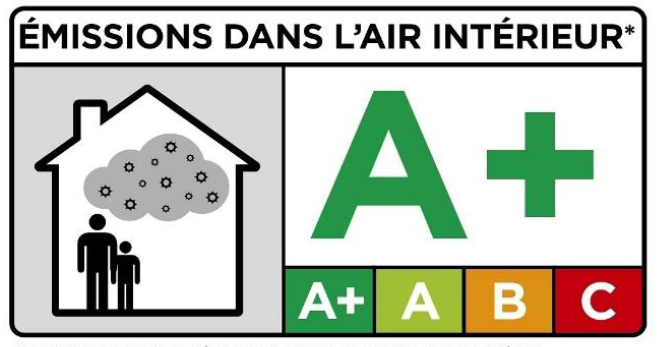

VOC Emission tests

Eurofins product testing, 2021

| - French VOC regulation (DEVL 1133129ª): |  |

| - French CMR components (DEVP0908633A and DEVP0910046A): | PASS |

| - Italian CAM Edilizia (GU n.259): | PASS |

| - ABG/AgBB (Ausschuss zur gesundheitlichen Bewertung von Bauprodukten): | PASS |

| - Belgian Regulation (C-2014/24249): | PASS |

| - Indoor Air Comfort GOLD (Eurofins): | PASS |

| BREEAM International: | Exemplary level |

| LEED v4.1 BETA: | PASS |